Wire Forming and Tube Bending for the Medical Sector

Wire forming is a process required to bend metal and bring it to customized shapes for manufacturing processes. AWC Industries provides custom tube bending and wire forming for many specific industries – including the medical sectors.

Custom Tube Bending Capabilities

we specialize in high quality CNC tube bending and fabrication, up to and including 3 inch diameter. We provide tube bending of ferrous and non-ferrous materials such as steel, stainless steel, aluminum, copper and brass. We are capable of handling both high volume production runs, and small orders. With our state of the art fabricating and tube bending equipment, we can assist you on any projects and provide the fastest turnaround time for the production of your products. Some of our typical tube bending products include dipstick tubes, pull handles, lifting handles, and bleacher end rails. Our objective at AWC Industries is to provide fast and quality tube bending service to help you meet your production needs and get your products out to your customers!

Custom Wire Forming Capabilities

A variety of components can be manufactured using our custom medical wire forming process. These types of wire forms are used as stand-alone medical device components or as parts in larger assemblies. Wire forming parts are combined with custom wire forming to produce the customer medical device requested. Additionally, our custom wire forming can be done with an array of metals such as steel, stainless steel, aluminum, copper and brass. In a custom wire forming process, our team can also make wires in various shapes such as round, flat, square or any custom designed shape.

Custom Wire Forming/Bending

AWC Industries is a contract manufacturer serving OEMs and researchers in the medical device industry. We use a combination of mandrel wire benders, press wire benders, draw wire benders, Vaill wire end formers and Tauring 3 ring wire rollers to produce our finished goods. No matter what shape of metal wire you want, whether it is round, oval, square or rectangle, we can help you meet your needs. Besides bending wires into various types of desirable shapes, we also provide them with fine finishing either with chrome plating, zinc plating or powder coating.

Metal Fabricating Equipment

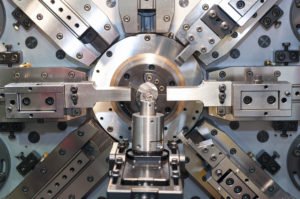

AWC is best suited to custom bend tubes and wires with sizes up to 1 inch diameter with our highly automated and high-precision CNC machinery: OMCG CNC Wire Bending Machines and IM CNC Wire Bending Machines.

The metal forming procedure is a combination of the following processes:

- Bending

- Forming

- Flattening

- Punching

- Drilling

- Coining

- Threading

- Straightening & Cutting and more.

When you get in touch with us, we will try and understand your specific requirements and make sure that your project priorities are duly met with. By working with us, you can be rest assured that your technical projects will achieve the highest zenith of success. Our technical team can provide you with the best expertise in the industry, and you can expect your finished goods at the earliest turnaround time.

Click here to request a quote or here to get in touch today.