A Deeper Dive Into the Premier Powder Coating Services at AWC Industries

Powder coating is an excellent choice if you’re seeking to augment a product’s aesthetic appeal or ensure its longevity against the elements. AWC Industries is a renowned name in tube bending and wire forming. They take this process to the next level by offering high-quality powder coating services. Continue reading here as we walk through the evolution and benefits of powder coating offered by AWC Industries.

The Evolution of Powder Coating

Powder coating is a dry finishing process that has become extremely favored since its introduction in the 1960s. In the not-so-distant past, liquid paint was the primary method to coat objects, offering color variety and aesthetic appeal. However, it fell short when it came to durability and environmental impact. The arrival of powder coating presented a solution to these shortcomings. The powder coating technique involves the application of a dry, free-flowing powder onto a surface, typically metal.

The powder is then heated (or cured) until it forms a smooth, hard layer. The result is a significantly more durable and eco-friendly finish than conventional liquid paint can offer. AWC Industries has embraced and enhanced this technology to provide its clients with top-tier powder coating services.

The Powder Coating Process

AWC Industries prides itself on a meticulous and well-structured powder coating process. The steps involved include:

- Preparation: The surface of the part to be powder coated is thoroughly cleaned and degreased. This crucial step ensures the removal of any contaminants, oils, or residues that may affect the adhesion of the powder coating.

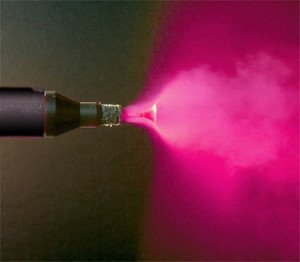

- Coating: Spray guns apply the powder coating to the part’s surface. This gun emits an electrostatic charge, which causes the powder particles to attract and adhere to the surface, covering it entirely.

- Curing: The coated part is then placed in a curing oven. The oven’s high temperature melts the powder, which fuses into a solid, durable, and attractive coating.

With a firm grasp on the careful and precise process involved, let’s shift our attention to the multitude of benefits that AWC Industries’ powder coating services bring.

The Benefits of Powder Coating

Powder coating is more than just an aesthetic upgrade. When you choose AWC Industries for your powder coating needs, you’ll experience several significant benefits:

Durability

Unlike traditional paint, powder coating is resistant to chipping, scratching, and fading, ensuring your parts maintain their appeal and function for longer.

Variety

AWC offers a wide range of colors and finishes. No matter the design or color scheme, they’ve got you covered.

Environmentally Friendly

Powder coating is devoid of harmful solvents found in liquid paint. This means fewer volatile organic compounds (VOCs) are released into the atmosphere, making it a greener choice.

Efficiency

The electrostatic application method allows for a uniform coating, reducing the waste commonly associated with liquid painting methods. Also, the new or over-sprayed powder can be collected and reused, reducing material wastage.

Cost-Effective

Given the durability, efficiency, and minimal waste associated with powder coating, it is often a more cost-effective option in the long run.

Having explored the many benefits of powder coating, partnering with a company that can guarantee precision, quality, and customer satisfaction is crucial. AWC Industries stands out as a beacon in the powder coating landscape, offering expertise, cutting-edge technology, and a dedication to excellence.

Final Thoughts

When you entrust your powder coating requirements to AWC Industries, you’re not just getting a service – you’re acquiring a partnership committed to bringing your vision to life with unmatched quality. For all your tube bending, wire forming, and powder coating needs, consider AWC Industries as your go-to partner.

Contact us today for a powder coating quote.