Your Premier Destination for CNC Wire Forming

Are you in search of a wire forming manufacturer? At AWC Industries, we pride ourselves on delivering exceptional CNC wire forming and fabrication services. Our expertise extends to handling materials up to 1-inch in diameter, using only the most advanced CNC forming equipment.

At the core of AWC Industries is our specialization in precision wire forming. Our comprehensive services encompass design, manufacturing, mechanical engineering, automation, quality control, and testing.

A Rich Heritage of Innovation

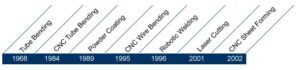

Founded in 1947 by two visionary brothers, AWC Industries began with the simple idea of crafting lamp shade frames. Over the years, we have significantly expanded our capabilities, marking our transformation from A-Wire Corporation to A-Wire & Tube Fabricating Corporation, and ultimately, to AWC Industries:

Our journey from creating decorative items like brass scrolls for headboards and point-of-purchase displays to large-scale storage systems for electronic voting booths, along with our in-house powder coating facility, reflects our unique industry perspective.

State-of-the-Art CNC Wire Bending

CNC wire bending, a key aspect of wire forming, leverages computer numerical control to shape wires into complex, intricate designs. This process is distinct from milling, as it begins with a solid block of material (typically aluminum) and shapes it using specialized tools without the need for support materials. The result is a precision-formed product, driven by advanced computer control.

Diverse Wire Forming Applications

Wire forming is crucial in various industries, including aerospace, construction, military, and furniture. At AWC Industries, we excel in high-end wire forming and metal bending, catering to both ferrous and non-ferrous materials like aluminum, brass, copper, steel, and stainless steel. Our top-tier CNC wire forming facilities can handle metal wires up to 1 inch in diameter, ensuring the highest quality output.

Why Choose Wire Forming?

Wire forming is not just a manufacturing process; it’s a way to infuse modernity and ease of use into your products. Our techniques, which include mandrel wire benders, press wire benders, draw wire benders, Vaill wire end formers, and Tauring 3 ring wire rollers, allow us to shape metal wires into any desired form, be it round, oval, square, or rectangle. We further enhance these shapes with finishes like chrome plating, zinc plating, or powder coating.

Partner with Us for Success

When you collaborate with AWC Industries, we take the time to understand your specific needs, ensuring that your project receives the attention it deserves. Our technical team, renowned for their industry expertise, is committed to delivering your projects with the quickest turnaround time. Trust us to elevate your technical projects to their highest potential.

Explore the diverse range of our popular products, including CNC and manual wire and tube benders/formers, and discover how our precision forming services can revolutionize your manufacturing processes. Contact AWC Industries today for a partner in success.